Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

Toys Testing Equipment

Toys Testing Equipment Physical & Mechanical Testing

Physical & Mechanical Testing Flammability Testing

Flammability Testing Clamps for Toys Testing

Clamps for Toys Testing Electronic Toy Testing Equipment

Electronic Toy Testing Equipment ISO8124-4,EN71-8

ISO8124-4,EN71-8 Footwear Testing Equipment

Footwear Testing Equipment Fatigue Testing Equipment

Fatigue Testing Equipment Flexing Test Equipment

Flexing Test Equipment Impact Testing Equipment

Impact Testing Equipment Abrasion Testing Equipment

Abrasion Testing Equipment Waterproofness Tester

Waterproofness Tester Friction & Slip Testing

Friction & Slip Testing Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Mattress Testing Machine

Mattress Testing Machine Table Testing Machine

Table Testing Machine Chair Testing Machine

Chair Testing Machine Textile Testing Equipment

Textile Testing Equipment Fabric and Garment Testing Instruments

Fabric and Garment Testing Instruments Color Fastness Testing Equipment

Color Fastness Testing Equipment

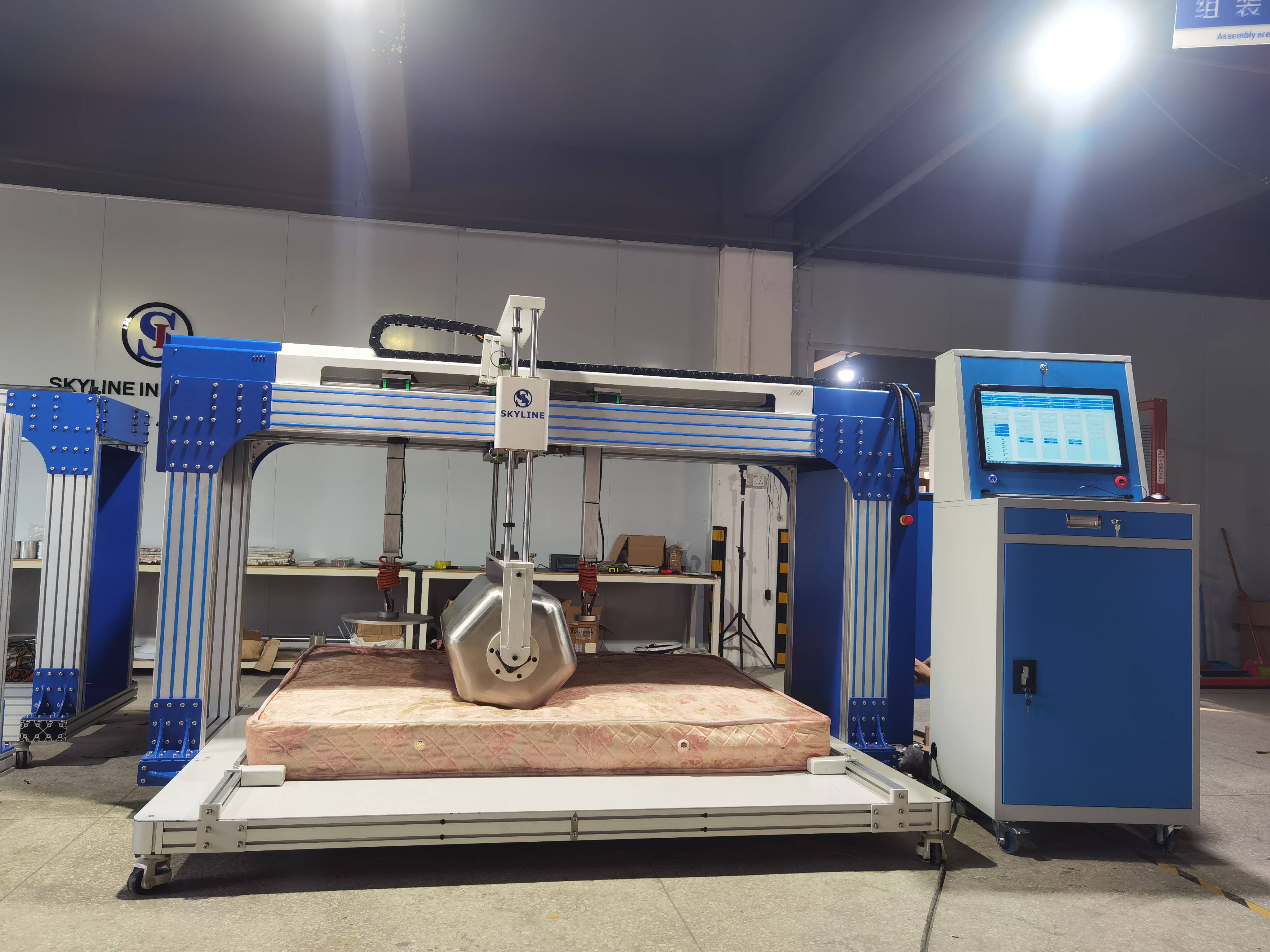

EN1957 ASTM F1566 GB Test standard Integrated Mattress Test Machine

Product Introduction

This machine is suitable for comprehensive mechanical testing of strong spring mattresses, ordinary spring mattresses, foam mattresses, and brown fiber elastic mattresses,it is a machine designed to simulate the constant rolling during human sleep.

At the same time, it is equipped with tests including height measurement, soft hardness and rolling fatigue; it meets the requirements of national GB, EN, ASTM and other test standards.

Test Standard

ASTM F 1566, EN 1957

Mattress Durability Test Applications & Test Purpose

Mattress Durability Tester using a horizontal hexagonal wooden drum roll or cylinder to rolling back and forth on the mattress, simulate human motion to assess the durability of the mattress.

1. The tester adopts a combination of thickened aluminum profile frame and steel, which is generous and stable as a whole; the base adopts a split design, which is more convenient for transportation and movement.

5.The fixture and rollers adopts movable installation, and the whole machine adopts open design, which is convenient for installation, debugging and machine transportation.

Technical Parameter

Capacity

2kN Sensor*1

Servo motor

0.4kW*1、1.5kW*1

Cylinder stroke

Stroke 500mm, Max thrust 1.39kN

Control mode

PLC and LCD Touch Screen Control System

Test Speed

10~20 times/min(EN 16±2 times/min,ASTM 20 times/min MAX)

Rolling stroke

Rolling 250mm left and right from the center

Total rolling distance from the center if 70% of the mattress , and the max is 965mm

Rolling drive

Servo motor with synchronous belt drive

Accuracy of detector

Displacement accuracy:±0.1mm; Loading accuracy ±0.1N(0.1-480N)

Roller(Optional)

EN Round Cylinder:140kg, Length 1000mm,Diameter 300mm, R20mm

ASTM Hexagonal barrel: 109kg,

Length 36±3in(915±75mm)

Rolling fatigue test

EN Round Cylinder: 30000 cycles

ASTM Hexagonal barrel:100000 cycles

Max. mattress size

2200x2200x400mm(L*W*H)

Power Supply

220V,50HZ(Korean Standard)

Main Test Items

Rolling Fatigue Test, Hardness Test, Height Loss Test

Click below to see how to change roller and compression plate for more details:

Toys Testing Equipment

Toys Testing Equipment Footwear Testing Equipment

Footwear Testing Equipment Tensile Testing Machine

Tensile Testing Machine Environmental Test Chamber

Environmental Test Chamber Building Material Flammability Test Equipment

Building Material Flammability Test Equipment Paper Testing Equipment

Paper Testing Equipment Spectacle Frames Testing Equipment

Spectacle Frames Testing Equipment Oil Analysis Testing Equipment

Oil Analysis Testing Equipment Lab Test Equipment

Lab Test Equipment Electronic Testing Equipment

Electronic Testing Equipment Stationery Testing Equipment

Stationery Testing Equipment Flammability Test Equipment

Flammability Test Equipment Furniture Testing Machine

Furniture Testing Machine Textile Testing Equipment

Textile Testing Equipment

English

English 中文

中文 Español

Español française

française العربية

العربية Русский

Русский

.png)